What kind of samples can be measured by laser Raman microscopy? And what kind of preprocessing do I need? This page describes the samples that can be measured and the simple pretreatment.

About the size of the sample and the required minimum amount

The microscope body used for laser Raman microscopy is a common optical microscope. Therefore, it is safe to imagine the size of the sample that can be placed on the slide glass. The following shows the sample size that can be installed and the required minimum sample size as a guide.

Possible sample size

Thickness: 2.5 cm or less

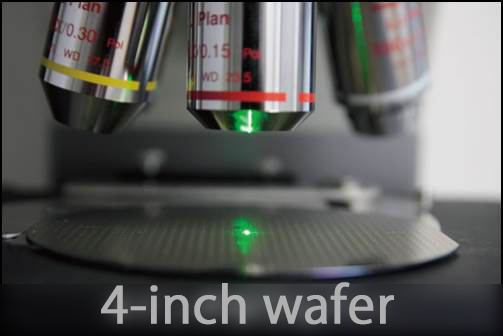

Flat size: about 10 cm square or less

An example of the photo is a 4 inch wafer. Note that these depend on the specifications of the optical microscope body. Please contact us for more information.

Required minimum sample amount

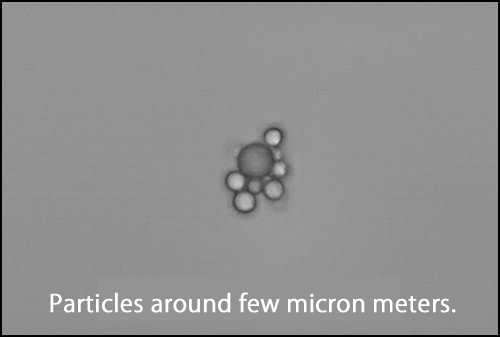

It is possible to measure even small particles (a few μm in diameter) for Raman spectrum measurement.

Sample pretreatment

When measuring a single-point Raman spectrum, it is not necessary to have a flat surface. On the other hand, when measuring Raman images, it is preferable to have a somewhat flat surface. Focusing is simplified over the entire measurement range, enabling measurements over a wide imaging area. The following example illustrates planarizing of solid samples, inclined samples, powder samples, and sol-based samples.

surface flattening of the solid sample

Prepare the surface with sandpaper. You can get a beautiful Raman image by using more than 600 pieces. The example of the photograph is an example of polishing the surface of a curved tablet.

Sloped surface

If the sample has a flat surface, but the sample tilts when it is placed, use a stage for correcting the tilt or a vise for the microscope.

Flat surface powder sample

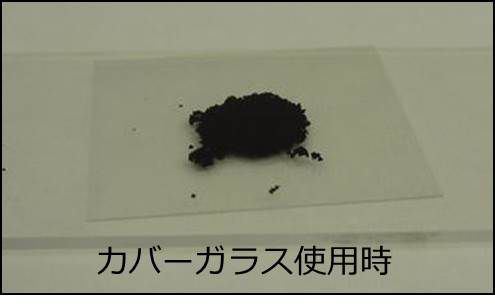

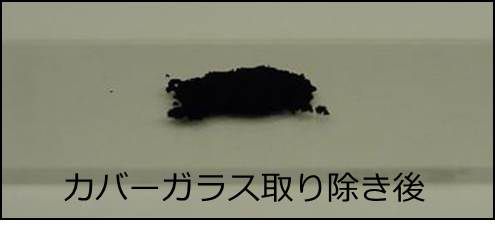

When measuring a single-point Raman spectrum using point illumination, even if there are irregularities, it does not matter much. When measuring Raman imaging, gently put the cover glass on a powder sample taken on a slide glass or the like, and measure as it is or gently remove the mounted cover glass. The Raman image while tracing the irregularities on the surface of the powder sample can be measured separately using the 3D-Build function.

Surface flattening of sol-based samples

Place the sample on a slide glass and gently place the cover glass and measure through the cover glass. A smooth surface can be obtained at the same time that moisture evaporation etc. can be suppressed during measurement. When measuring with the cover glass removed, slide the cover glass sideways at a constant speed to expose a smooth surface. The photo is an example of planarizing a mayonnaise sample.

Sample fixing props that require attention

You may use tape or clay to fix the sample, but do you know that there are points to be noted? Here are some points to keep in mind when using double-sided tape, carbon tape, and clay.

Double-sided tape

The sample may slip until the adhesive settles down. If it measures several hours after installation, it can measure enough even with a 100x objective lens.

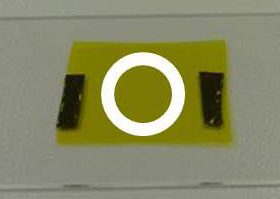

Carbon tape

If you attach a transparent film to carbon tape and fix it, the carbon tape will burn before the film and can not be measured. Attach it to both ends of the sample so as not to disturb the measurement.

Clay

Although it is effective for tilt correction, it is necessary to pay attention to the displacement due to plastic deformation of clay. If deviations are a problem for long-term measurements, other fixing methods are recommended.