News

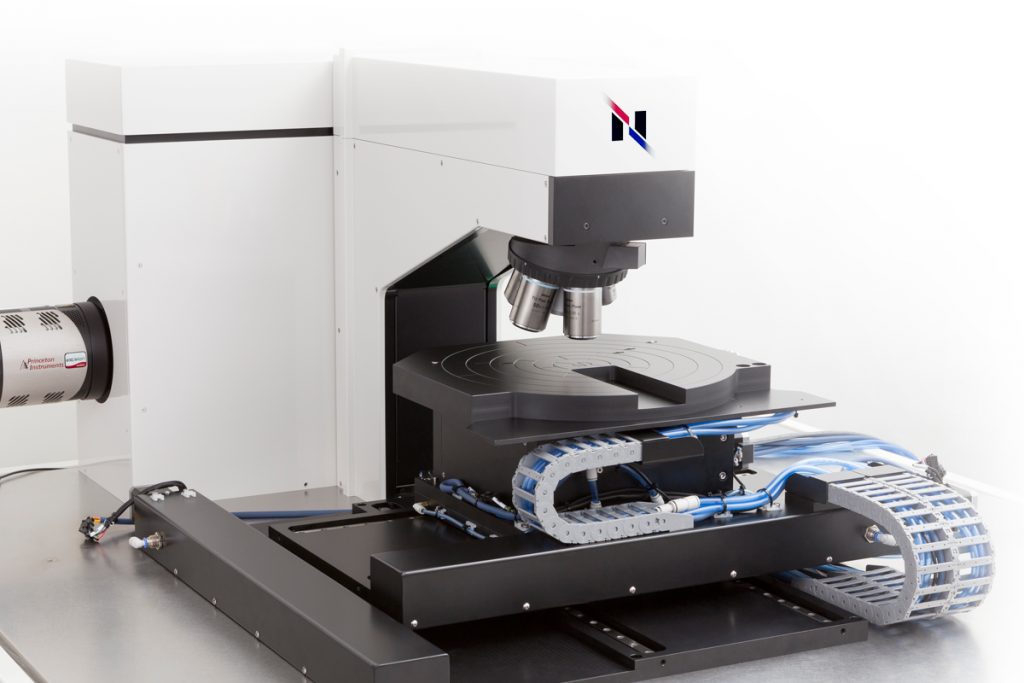

Nanophoton introduced RAMANdrive – a new Wafer Analyzer – for a wide range of applications at semiconductor market at ICCGE-18 (the 18th International Conference on Crystal Growth and Epitaxy) in Nagoya, Japan, August 7th – 12th, 2016.

With sub-micron resolution, RAMANdrive provides stress-, polytype-, defect distribution etc. in 3 dimensions using the most powerful Raman Imaging Technology of Nanophoton. The dedicated 300 mm stage was developed for accurate and safe analysis of the whole wafer, while the Raman Imaging System provides you with high performance data. Especially the unique Nanophoton Stage Navigation System features easy and fast operation by implementing your data from the regular inspection system and use it to move the wafer to all positions you are interested in for a detailed analysis.

Michael Verst – President/CEO of Nanophoton – commented: “Raman Imaging is one of the most exiting technologies for wafer analysis. It provides comprehensive data about stress, polytype, impurity or contamination non-destructively in all 3 dimensions. In combination with our dedicated 300 mm wafer stage, I strongly believe that our RAMANdrive will be a powerful tool especially for QA/QC as well as development work. It will substantially improve the yield ratio, but also accelerate the development of new materials etc. Nanophoton invested a substantial amount of efforts in the development and during all the time we worked closely with related experts to meet the requirements of our customers in the semiconductor industry.”

The unique features of RAMANdrive

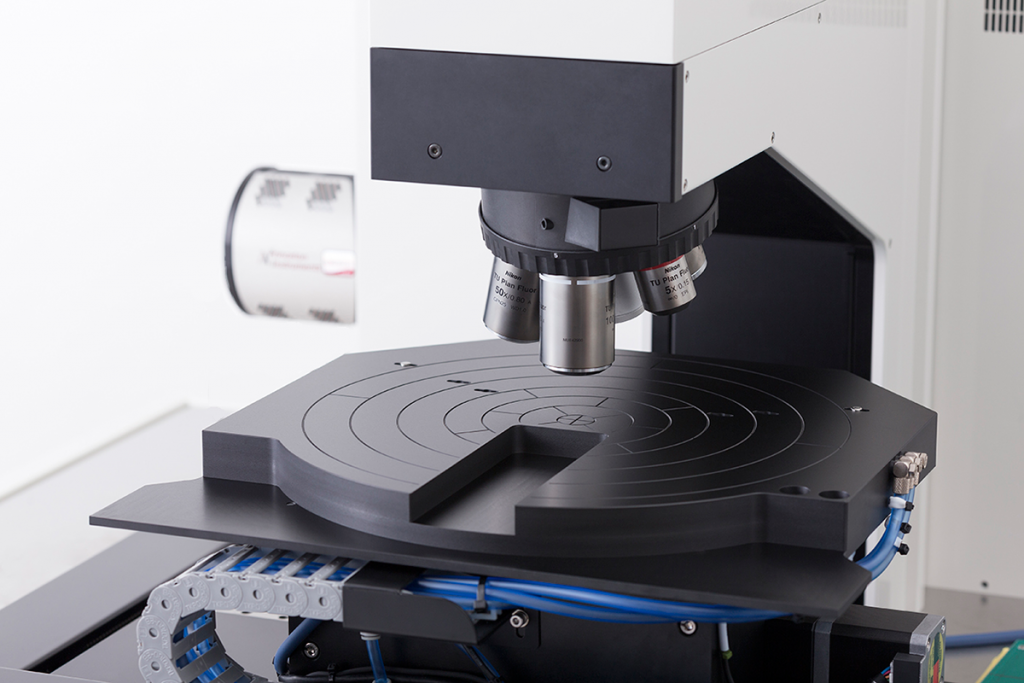

1. Stage Navigation System

The Nanophoton Stage Navigation System implements your data from your inspection system and use it to move the wafer to all positions you are interested in for a detailed analysis. The dedicated stage moves the wafer safe and with high accuracy to all areas of interest.

2. Identi cation of particles even smaller than 100nm

RAMANdrive uses high-quality dark-field microscopy to easily localize particles, even smaller than 100 nm. The analysis of the particle is done by highest performance Raman spectroscopy and provides detailed analysis of the composition of the material.

3. 3D stress observation by powerful Raman Imaging.

High quality confocal optics gives RAMANdrive highest performance 3D Raman Imaging capability. Stress distribution and polytype distribution can be clearly visualized in 3D with submicron resolution.