Email Magazine

Case Studies (12/23/2020)

KOBELCO RESEARCH INSTITUTE. INC which is Kobe Steel Group, introduced Nanophoton’s RAMANtouch laser Raman microscope in October 2019. (Kobe City), a testing and research company, introduced Nanophoton’s RAMANtouch laser Raman microscope in October 2019. The company conducts a variety of contract analysis, testing, and analysis brought in by companies and research institutions in Japan and overseas. How is the Raman microscope of Nanophoton useful for the company, which is a professional analysis company? We visited the Chemical Analysis Center at the Takasago Plant (Takasago City, Hyogo Prefecture). (e-mail Newsletter editor-in-chief / freelance writer Takeshi Nemoto)

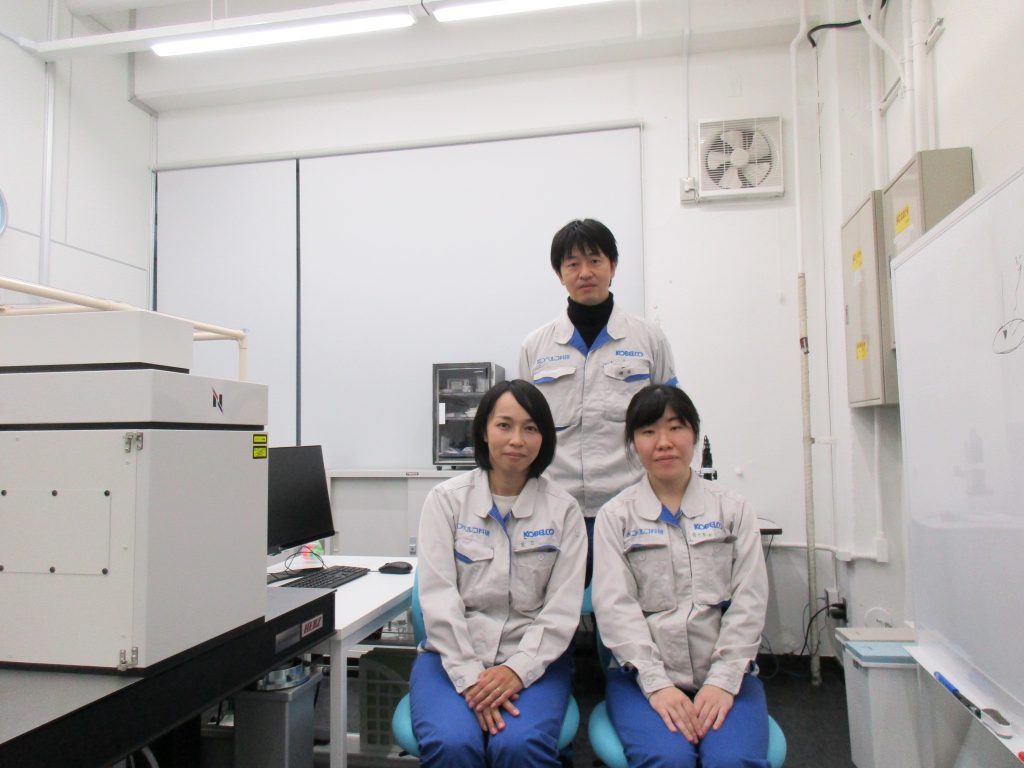

Chemical Analysis Center, Takasago Works, Technical Division, KOBELCO RESEARCH INSTITUTE. INC

Mr. Isoo, General Manager of the Chemical Technology Office, and Mr. Adachi and Mr. Sasaki of the Analysis Office, who use the Raman microscope on a daily basis, agreed to be interviewed. Mr. Adachi and Mr. Sasaki are mainly in charge of spectroscopic analysis, and Mr. Sasaki, in particular, uses the RAMANtouch every day to make measurements.

Supporting customers in solving their problems through analysis and testing based on chemistry

The company was established in 1979 and has been supporting customers in solving their problems with the latest equipment and technology, from analysis, analysis and measurement to prototyping and manufacturing. In the “contract testing and research” business, which provides services such as analysis, testing, and analysis, they deal with a wide range of fields, including transportation equipment, electronics, energy, and the environment.

Mr. Isoo: “At KOBELCO, we not only report the results of our analyses and tests, but we also focus on providing our customers with insights and proposals to solve their problems. Our Chemical Analysis Center conducts analyses, tests, and experiments based on chemistry, and our chemical experts provide solutions to solve our customers’ problems based on various data.

Judging from the measurement speed and sensitivity, purchase RAMANtouch.

Although they have owned Raman microscopes for a long time, the performance of Raman microscopes has improved dramatically in recent years. They started to consider purchasing a new model to meet the ever-changing needs of their customers.

Mr. Isoo: While comparing it with other companies’ products, we comprehensively looked at speed, data stability, sensitivity, data analysis tools, and ease of use, and came to the conclusion that Nanophoton’s RAMANtouch was the most suitable for our needs. In fact, when we brought the samples to Nanophoton and showed the measured data within the company, the quality of the data became a hot topic. In addition to the performance of the equipment, we were also impressed by the fact that Nanophoton would provide us with all kinds of consultation services even after the introduction of the equipment through our communication with the person in charge.

Now, what is the specific role of RAMANtouch in the company? Mr. Isoo gave us three examples: semiconductors, metal corrosion, and secondary batteries.

Line lighting is a powerful tool for semiconductor analysis.

In the case of semiconductors, the line illumination and imaging functions of RAMANtouch are very effective in evaluating stress, crystallinity, and defects. Line illumination is Nanophoton’s unique technology that enables high-speed imaging by simultaneously detecting Raman scattered light emitted from 400 points by irradiating a sample with a laser beam stretched in a line. In the past, Raman scattering light was measured by irradiating the laser beam one point at a time.

Mr. Ishoo: Especially for flat semiconductor substrates, line illumination is very useful, and it helps us to obtain high-definition Raman images in a short time. Recently, we have received many requests for the evaluation of silicon carbide (SiC) and gallium nitride (GaN), which are increasingly used as materials for power semiconductor devices. RAMANtouch is now very active in semiconductor analysis.

Also used in metal corrosion evaluation

As for metal corrosion, they often do corrosion evaluations because their parent company is involved in metal-related businesses.

Mr. Ishoo: Since the Raman spectrum was clearly detected, it became much easier to analyze the components, such as identification. In addition, the Raman image that shows the distribution of corrosion products is very clear, and I honestly thought it was amazing. In addition, the high detection sensitivity enables measurement in a short time, which reduces the risk of sample alteration, and the measurement area can be freely selected from small to large areas. In that sense, too, we can perform analysis that matches our customers’ needs.

Rising Expectations in Rechargeable Battery Evaluation

And the secondary battery.

Mr. Isoo: Raman microscopy is very effective in evaluating the condition of electrodes and electrolytes in lithium-ion batteries and all-solid-state batteries, which will be commercialized in the near future. For example, it is important to evaluate the state of the battery in real time in order to know what causes the characteristics and degradation of the battery during repeated charging and discharging. As long as the laser is focused, the Raman microscope can measure the state of the battery as it is, so it can be applied to such needs. In particular, RAMANtouch has various functions necessary for the evaluation of secondary batteries, and we have high expectations for it in our company. Both rechargeable batteries and semiconductors are undergoing technological innovation on a daily basis, and we believe that we must respond to such changes in the situation.

Raman microscope is an important weapon.

The company not only analyzes the samples that are brought in, but also provides support in solving problems. This is how we support Japanese manufacturing and technological innovation.

Mr. Isoo: In the past, various settings were required to obtain a single piece of data. Recently, however, it has become possible for anyone to obtain data of a certain quality at the push of a button. I think this contributes greatly to productivity, but in order to obtain high quality data, it is necessary to have a precise understanding of the principles of analysis and the mechanism of the equipment. Furthermore, we believe that we have a responsibility to not only obtain high quality data, but also to return it with added value.

For example, let’s say that a part manufactured by a customer has a defect. When we are asked to clarify the reason, we take data from all perspectives using various analytical methods and analyze them comprehensively to formulate our findings. In some cases, this leads to the elucidation of new phenomena rather than defects. Nanophoton’s Raman microscope is an important weapon to help customers solve their problems and support their research and development.

What are your impressions of the actual operation of the system?

We asked the employees who actually use the system what they think about its operability and performance.

Ms. Sasaki: The ability to switch lasers with a single click and the flexibility in setting the power are very useful for adjusting conditions. Also, I can analyze while measuring, which has improved my work efficiency.

Ms. Adachi: The Raman imaging is beautiful. I also like the fact that the power can be adjusted in real time while the laser is being applied. I also appreciate the quick response to my inquiries to Nanophoton.

Ms. Sasaki: And I appreciate Nanophoton’s service whose response is very polite and fast.

I strongly felt the importance and potential of Raman microscopy in analysis when we talked about it. Dr. Isoo also spoke as follows.

The good thing about Raman microscope is that it can provide various outputs for various needs in all industrial fields. It can be used for analysis to get a complete picture of a sample, and it is also useful for analyzing microscopic areas in fields where miniaturization and complexity are increasing, such as in electronic devices. Furthermore, since the equipment is very good at visualizing all kinds of information as images, customers are pleased to see that the data is very easy to understand. As you can see, I think this equipment is very well suited to the needs of the world.