Email Magazine

e-mail Newsletter #12 (10/14/2020)

Last time, we measured the plastic packaging of bonito flakes using a Raman microscope and confirmed the multilayer structure of polyethylene (PE), polyethylene terephthalate (PET) and polypropylene (PP). I was surprised to find that the “packaging” of bonito flakes was not just a transparent plastic, even though it turned into “plastic waste” the moment all the contents were removed. Realizing the fun of Raman microscopy to see through multi-layered structures, that is, to see what was invisible, we will measure food packaging again. This is secretly what I call “free research for adults”. Please feel free to read it with that in mind. (Newsletter editor-in-chief Takeshi Nemoto / freelance writer)

The “RAMANtouch” allows us to measure depth without cutting the sample. To put it simply, it is similar to a CT scan where you can obtain cross-sectional images without cutting the body. Again, it did not take much time to prepare the samples, and the measurement took only a few minutes per sample.

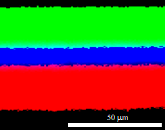

First is the packaging film for the sliced ham.

As a result of the analysis, three layers of polypropylene (PP), polyethylene terephthalate (PET), and polyethylene (PE) were identified. This is the same structure as the packaging of bonito flakes that we measured last time.

So what function does each layer perform? While researching on the Internet, I found a pamphlet from the Japan Plastics Industry Federation, entitled “Advantages of Plastic Containers and Packaging for Food.

The pamphlet shows examples of packaging materials for bonito flakes and ham, and the functions of each layer. Our measurements this time did not match the configuration examples, but it seems that polypropylene is responsible for moisture-proofing and antistatic properties (preventing bonito flakes from scattering due to static electricity), PET for rigidity and aroma retention, and polyethylene for adhesion.

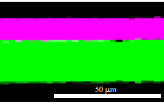

The results were almost identical to those of the other two materials (rot cover materials). The functions of polyamide are strength, oxygen barrier, and surface tension suitability, while polypropylene (PE/PP in the data) is listed as sealing properties.

The pamphlet states, “Tofu has been known since ancient times as a source of high-quality plant protein, but due to its fragility and short shelf life, people used to go to the tofu shop with the container each time they wanted tofu. Since the development of plastic tofu packages, it has become possible to buy hygienic and inexpensive tofu at any time that meets the storage requirements.

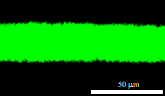

Next was the lid of the natto. I was expecting a multi-layered structure to prevent the smell from leaking out, but it turned out to be a single layer of polypropylene.

This reminded me of a topic that was discussed on NHK’s morning information program. The program introduced bread bags as a bag that would be useful in evacuation centers during disasters, as it would not leak odors. Bread bags are also made of polypropylene. The program explained that “compared to polyethylene, polypropylene allows only about one-half to one-third of the gas to pass through. However, the gas barrier property (the ability to block gases) of polypropylene is not particularly high among the many plastic materials, and it is possible that the thickness and additives have been devised.

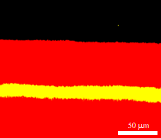

We also measured a variety of packaging, but the results were all the same. When I was thinking, “If only there were more variations,” Mr. Shimabata gave me an additional measurement of a mayonnaise container later. When he told me that he was able to measure EVOH (ethylene-vinyl alcohol copolymer) in the surface layer, I was so excited.

There is. I was also curious to read in the pamphlet of the Japan Plastics Industry Federation that it is used to prevent oxidation and loss of flavor in foods. Here is the quote from the pamphlet again

“Glass bottles used to be the only container for mayonnaise, but plastic blow-molded bottles were developed that were harder to break, lighter, more flexible in shape, and easier to squeeze out. Today, in order to maintain the quality of the contents, the bottles are made of multiple layers of plastic to improve the oxygen barrier.

There are many types of plastics, each with its own function to protect the flavor, freshness, and other qualities of food. “It can be said that today’s food culture is supported by plastics. However, it should be noted that while plastic is convenient, the fact that it is highly functional (multi-layered) makes recycling (material recycling) difficult. Since plastic waste is a mixture of various materials, it is not possible to melt it with heat and solidify it to use it as plastic again.

Because I was able to “visualize” the multilayered structure of the packaging plastic using a Raman microscope, I was able to investigate and think about the functions of plastics. Visualization, or imaging, is very important. I will continue to work on “free research for adults” whenever I get the chance.