Email Magazine

e-mail Newsletter #11

The other day, a university professor who studies plastics told me that the plastic used in food packaging is multi-layered. He told me that the plastic used in food packaging is made up of multiple layers of plastic, each with its own function, such as preventing oxygen permeation and puncture. However, no matter how carefully I looked at it, it looked like a single transparent sheet. So I thought, “Maybe a Raman microscope can help me identify them,” and asked a Nanophoton employee to measure them. (e-mail Newsletter editor-in-chief Takeshi Nemoto / freelance writer)

The multi-layered plastic used to package food is called “laminated film” (multilayered film), and it seems to be used in many products with advanced functionality.

The professor was talking to me about plastic recycling. He told me that it is difficult to recycle multilayer films directly into raw materials for plastic products because they are made of different types of plastics. The professor said, “That is one of the major issues in recycling. For food manufacturers, safety is also important, and it is a very difficult problem.

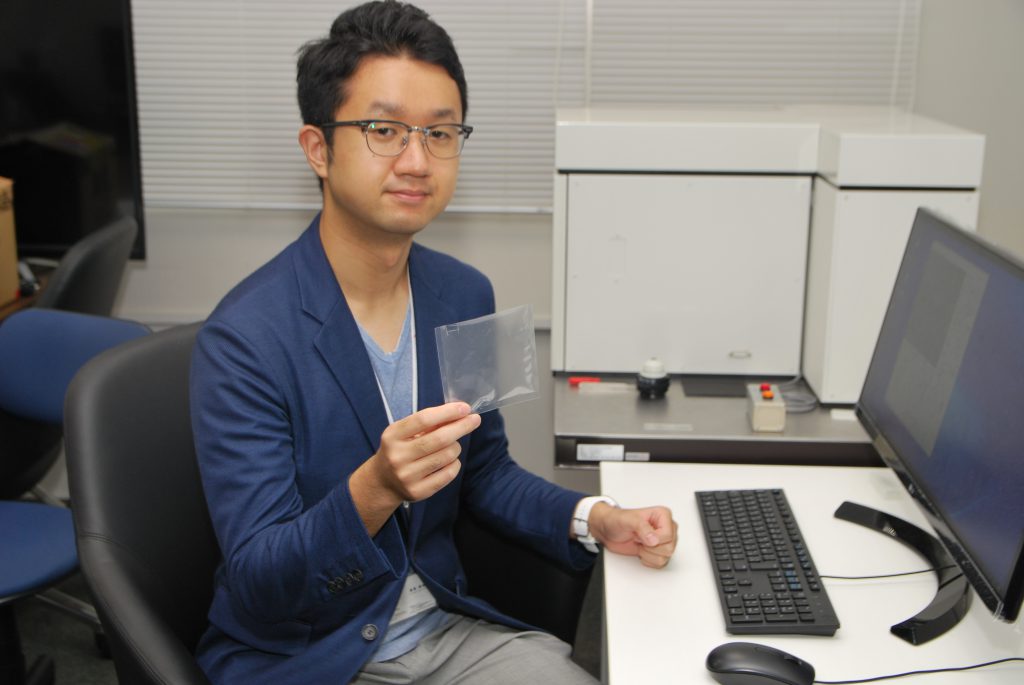

Now, we are going to measure with the Raman microscope. For this sample, we used a package of bonito flakes. It is a pack of dried bonito shavings divided into small portions. I told Nanophoton that I wanted to measure it, and Mr. Yosuke Shimabata, who is in charge of the service, prepared two kinds of films for me.

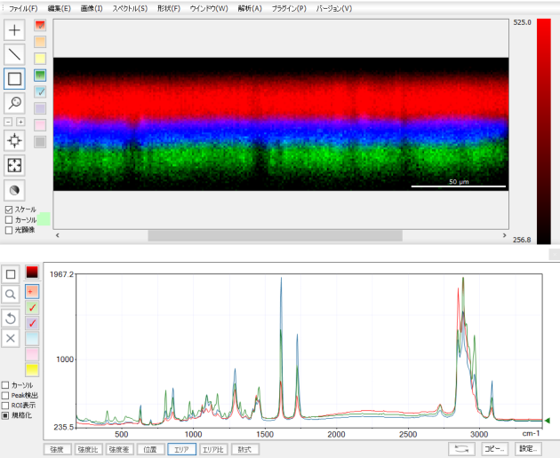

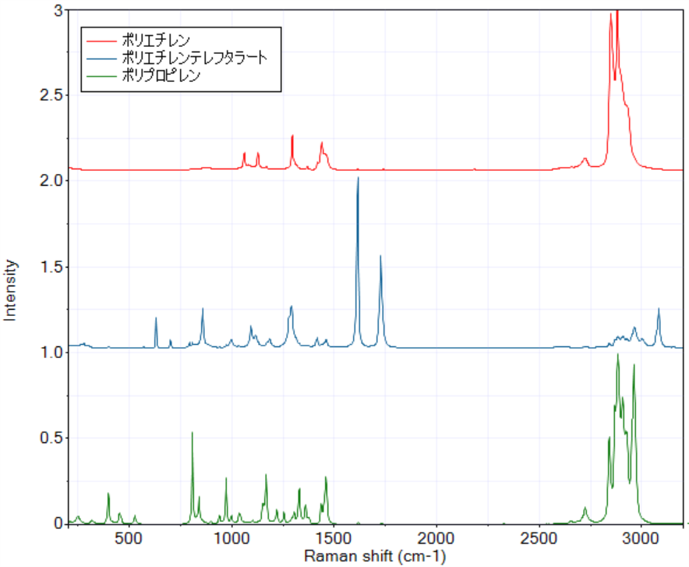

Here is a review of Raman microscopy. When a laser is shone on a molecule, scattered light is emitted. Most of the scattered light is of the same wavelength as the laser, but a small amount of light of different wavelengths is also included. This small amount of light is called “Raman scattered light,” and it includes light of various wavelengths. A graph (spectrum) of Raman scattered light separated by wavelength shows different characteristics for each molecule, so analyzing Raman scattered light can tell us what kind of molecule it is. Based on the characteristics of Raman scattered light, molecules are color-coded and their distribution can be seen in the field of view of a microscope, which is the Raman microscope.

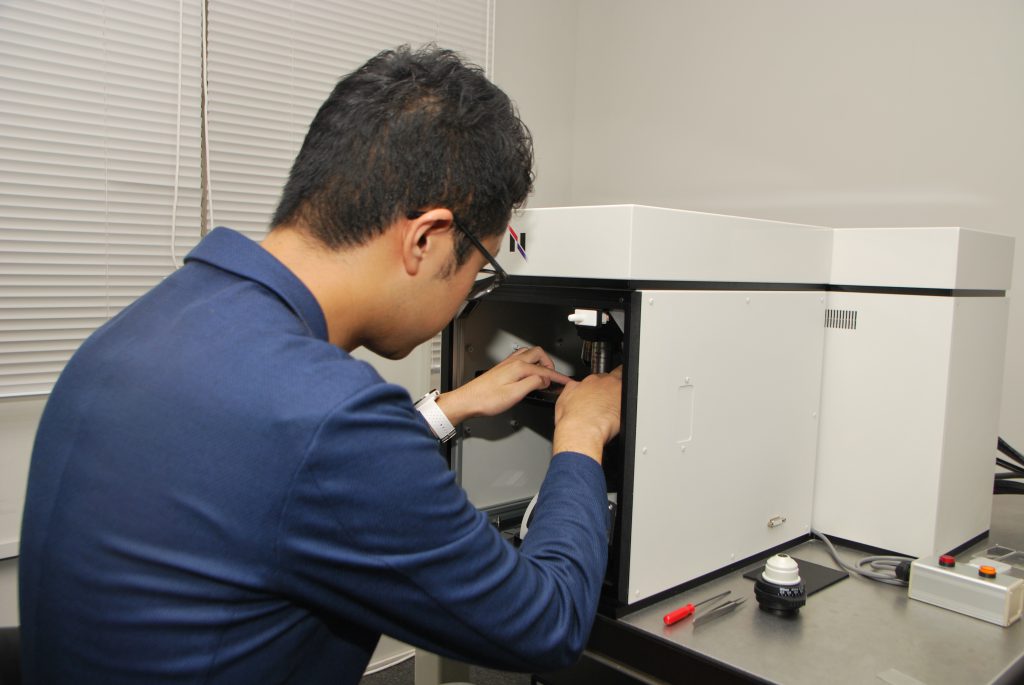

Back to the bonito packets. We used the RAMANtouch, which has high spatial resolution and high speed. We cut a small piece of film from the pack, placed it on a glass slide, and set it on the device. The rest of the operation is done on the computer. In this case, we wanted to see how the layers were organized, so we measured in the depth direction. One of the features of the RAMANtouch is that you can see the fault image without cutting the sample.

“After you set the conditions, just press the start button and the measurement will start automatically,” Shimabata said. The measurement was completed in about two minutes and thirty seconds while he explained further. The overall thickness of the film was about 60 micrometers.

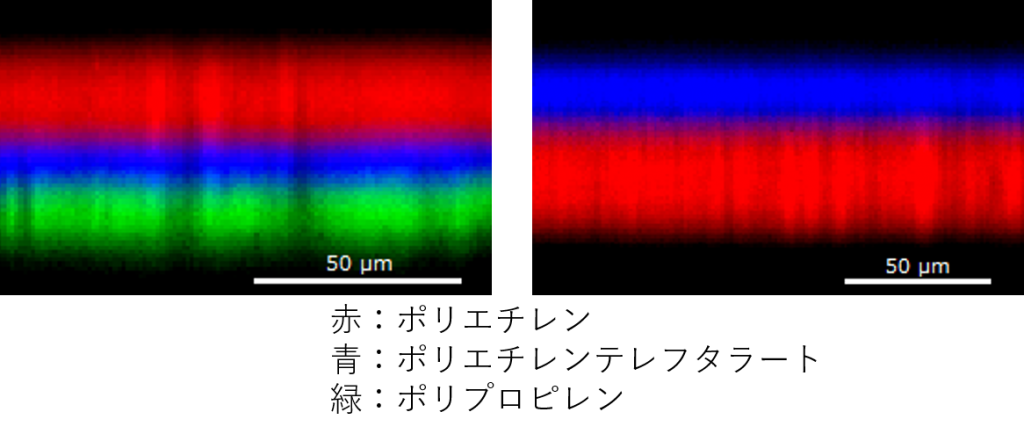

When color-coded by the characteristic peaks in the Raman spectra of the measured molecules, they appeared to be neatly divided into three layers. The plastic types, in order from top (outside the pack), are polyethylene, polyethylene terephthalate (PET), and polypropylene. Mr. Shimabata measured them beforehand and found out as a result of searching in a spectrum library where tens of thousands of Raman spectra are registered.

When we measured the film of the other type of bonito flakes pack, we found that it has two layers: polyethylene terephthalate on top and polyethylene on the bottom. It turns out that the composition of the film differs from manufacturer to manufacturer.

Even a transparent sheet of plastic looks completely different when measured with a Raman microscope. There is a big difference between just hearing about multilayer and actually seeing it with your eyes. It was a very interesting experience. Plastics are very deep. I will continue this topic for a while longer.

※Added on October 2, 2020

In the manuscript uploaded on September 30, the name “polystyrene” for the top layer of the other type of film was an error for “polyethylene terephthalate”. It has been corrected.

In addition, the figures in the article have been revised and replaced for easier reading based on the measurement data at the time of the interview.