Email Magazine

Path to mastery_5

This time, I tried Nanophoton’s wide-field Raman scope, RAMANview, which is ideal for observing samples as small as 1 cm in size. It is also designed to measure samples in bottles, packs, and even tablets with curved surfaces. As a first step to mastering its use, we measured a variety of items. (Takeshi Nemoto, Editor-in-Chief of the Email Newsletter / Science Writer)

Measurement in vial

For a detailed explanation of RAMANview, please click here. RAMANview was previously introduced in this corner under the title “Developed with the aim of being ” parcel delivery”“. RAMANview is a device that allows you to see the whole picture of a medicine pill or a rock, and is characterized by its compact and lightweight body that can be carried easily.

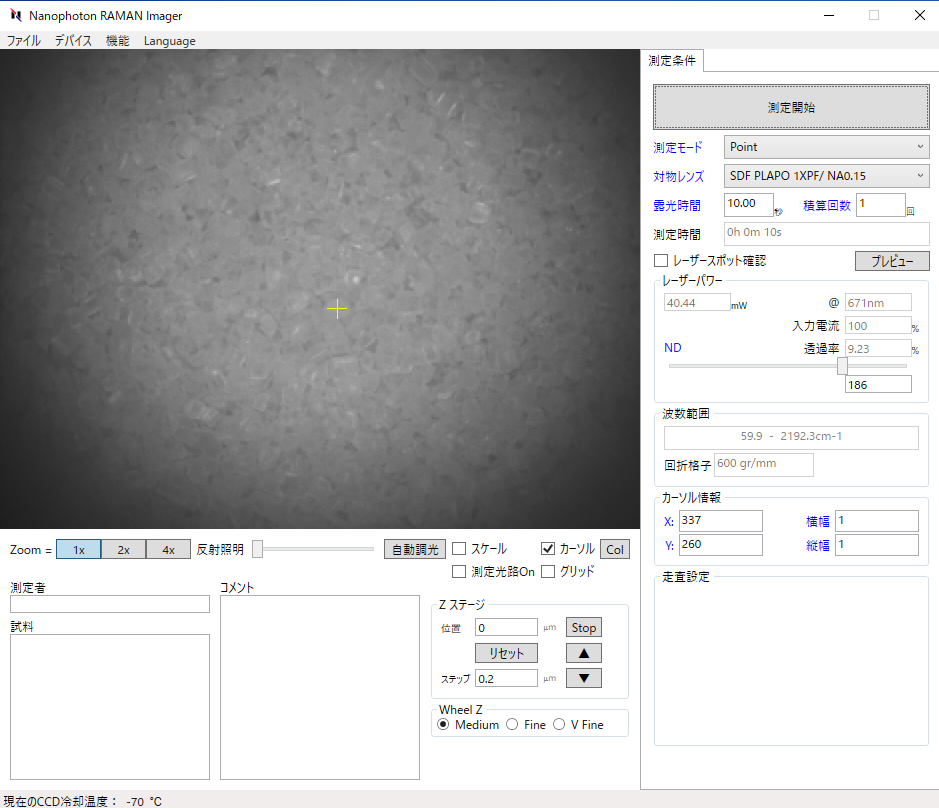

The laser wavelength is 532 nm or 671 nm, and the objective lens is selected from 0.3 to 2.0x. In the case of the 1.0x objective, the measurement range of the Raman image is 1.25 x 1.25 cm and the spatial resolution is 6 μm.

The employees seemed very busy, so after they showed me the basic usage, I measured various items by myself.

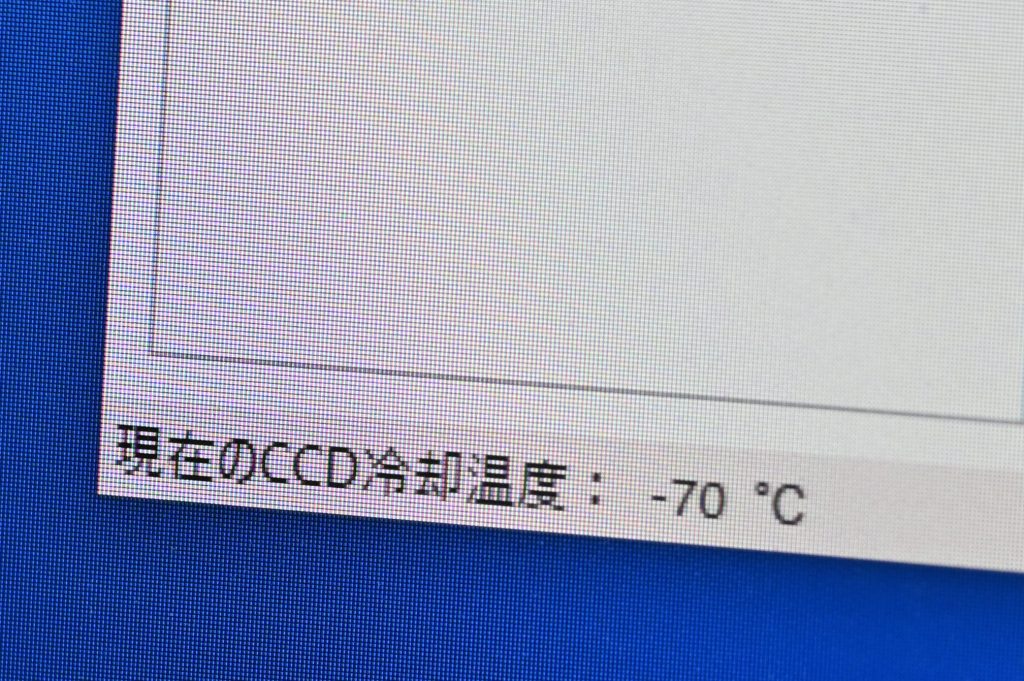

Now, first, switch on the device. Wait for about 1 hour to allow the instrument to stabilize. During this time, the temperature of the CCD detector, which detects Raman scattering light, drops to -70°C.

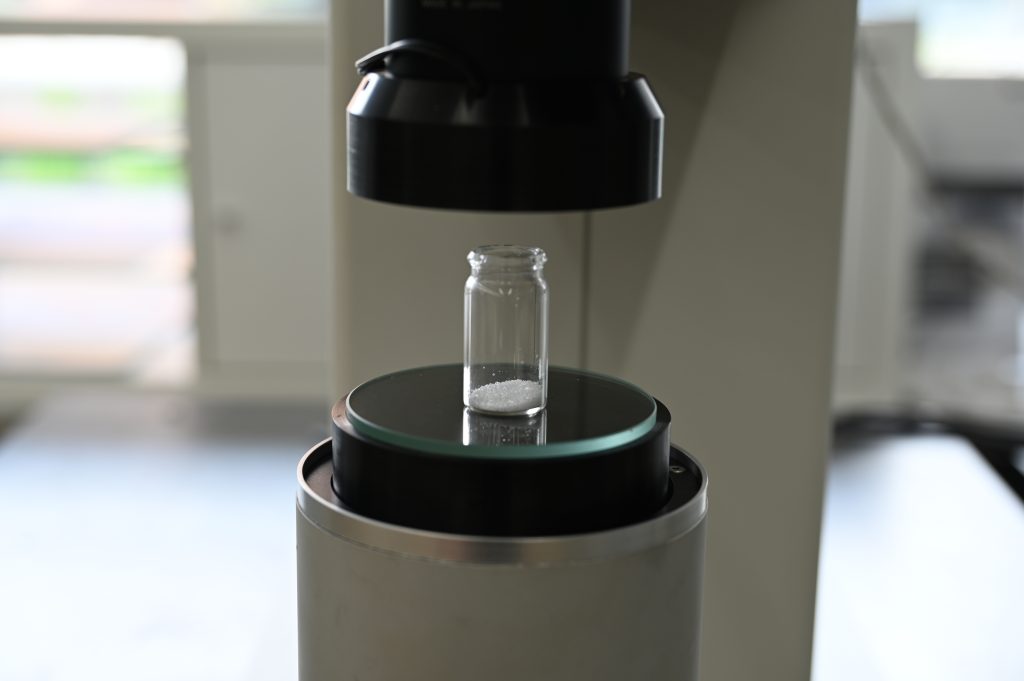

One of the features of RAMANview is its ability to measure even samples at the bottom of the container. Taking advantage of this, we will first measure sugar in a vial. Using a vial is a great way to easily measure liquid or granular samples.

The shading cover is lifted from the bottom and set in place.

Once the light-shielding cover is closed, the stage is raised and lowered and the measurement position is set entirely on the software.

Focusing is done by moving the stage up and down with the mouse wheel. Next, if you want to obtain a Raman image, simply set the range on the screen; if you want to obtain a spectrum of a single point, simply click at the desired location. The laser beam will move and take measurements at the specified range or position. The exposure time and laser power must also be determined, but we first had an employee set these up for us, and then we changed them little by little through trial and error.

Analyze Ingredients

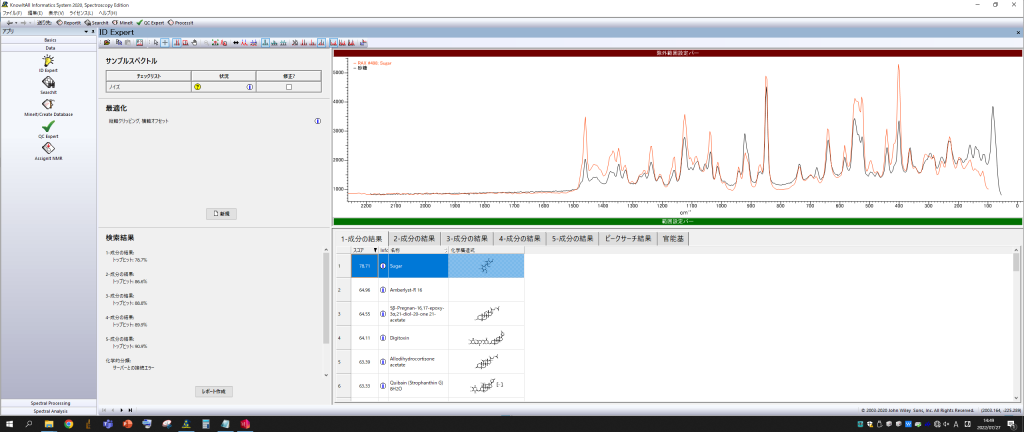

This time, we did not try imaging to visualize the distribution of components, etc., but instead measured points. After pressing the “Start Measurement” button and waiting a few seconds, the spectrum data is displayed. When I searched for this in “KnowItAll” in the Raman spectral database, “Sugar” was displayed at the top of the list. It seems that I was able to measure it properly.

In addition to this, I measured various other liquids around us, such as disinfectant sprays, in vials. I have already measured a variety of liquids. In the future, we would like to try using different lasers and objective lenses for further measurements. The disinfectant spray was a product with a mixture of various ingredients, but we obtained a spectrum that was almost identical to that of ethanol.

What about the mouth of a plastic bottle?

What else shall I measure? I was thinking, “Let’s try solids,” and then I remembered something that had been on my mind for some time. Plastic bottles. When you dispose of PET bottles as recyclable waste, you remove the caps and labels of “plastic containers and packaging,” right? However, there are PET bottles with white drinking cups, right?

I wonder if this white part is PET (polyethylene terephthalate). If it is not PET, I wonder if it is OK to mix it in. I was wondering that.

Therefore, I decided to measure a PET bottle with a white drinking spout using RAMANview.

It is because of RAMANview that you can set it up like this and measure any position you want. We measured the white and transparent areas respectively and compared the spectra.

I was later told that a 532nm laser is the best way to properly examine whether it is PET or not. Even so, both the white and transparent spectra showed peaks characteristic of PET. Despite the color difference between white and transparent, it seems safe to conclude that both are PET.

Actually, I found the answer on the Internet. In the “Frequently Asked Questions” section of the soft drink maker Daido Drink Co.

Q: Some PET bottles have a white mouth. Is the material the same as that of the container itself? Also, what is the difference between bottles with white mouthparts and those with transparent mouthparts?

From the DAIDOH LIMCO website

My question, that’s the one. The answer to my question was “the container and drinking spout are the same PET resin”. For more information, please see the Daido Drink Co. website.

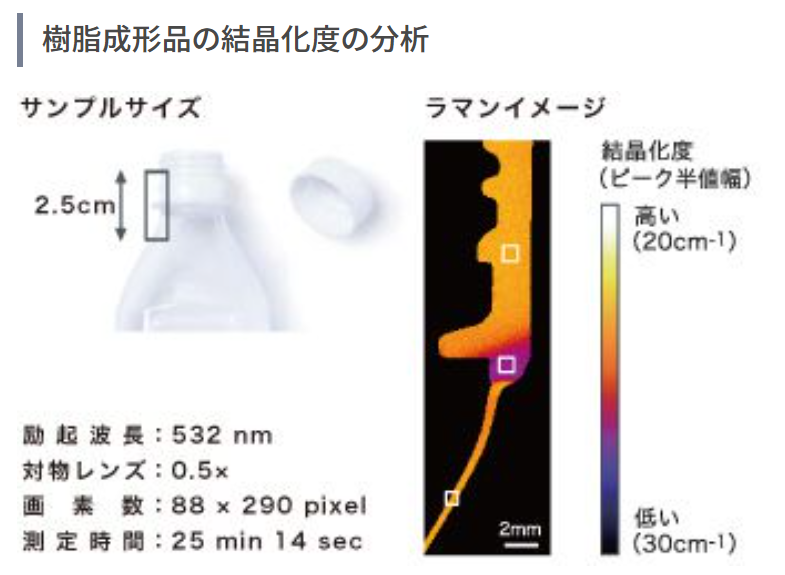

According to this website, the white color of the drinking spout is due to heat treatment and crystallization to make it heat resistant. Come to think of it, Nanophoton’s website “Analysis of Crystallinity of Resin Molded Products” visualizes the difference in crystallinity from the drinking spout to the body part of PET bottles.

I would like to try this “visualization of crystallinity” eventually.

This time, I measured this and that to familiarize myself with RAMANview’s operation. After all, practice is the best way to become proficient.